Introduction

A pre-trip check is part of a truck driver’s daily routine, for safety and compliance. A thorough pre-trip inspection will prevent accidents and mechanical failures on the road, not just for the driver but for other road users. Regulations require these checks for commercial vehicles so it’s a big responsibility for every truck driver. Beyond compliance, a detailed pre-trip inspection will identify potential problems before they become major issues, and reduce downtime and maintenance costs. This proactive approach will make overall operations more efficient and a smoother journey.

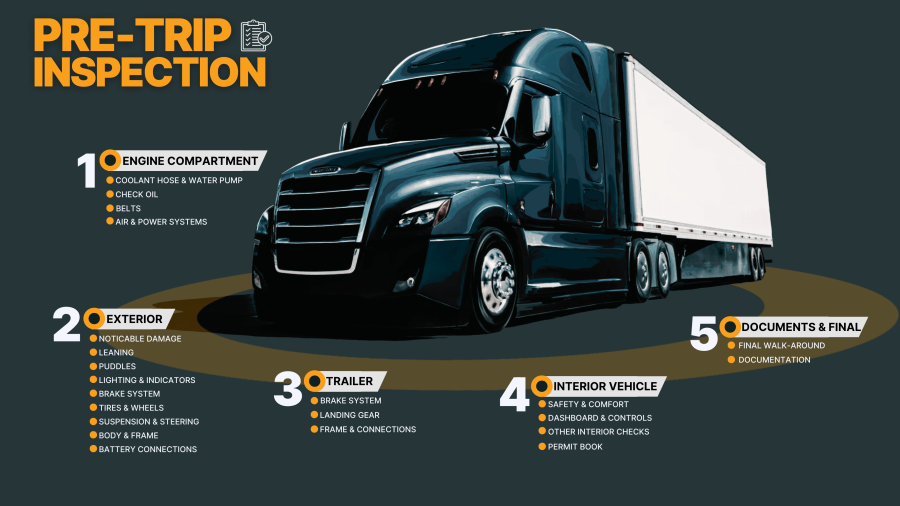

Pre-Trip Inspection Process

The pre-trip inspection process is a thorough examination of the truck to make sure it’s in good working order before you hit the road. This inspection covers brakes, tires, lights, steering, and suspension.

The checklist is a guide for drivers to methodically go through each item, nothing gets missed. By using this checklist drivers can identify any potential issues that can compromise safety or cause breakdowns. Using the checklist effectively means taking the time to inspect each item properly, note any defects or concerns, and fix them before you leave.

Pre-trip inspection reports are key to vehicle safety and compliance. These reports are a record of the inspection, documenting the condition of the truck and any issues found during the process. They are proof that the driver has done the checks which is important for legal and insurance purposes.

Also, these reports help fleet managers to track the maintenance needs of their vehicles, so repairs can be done on time and reduce the risk of breakdowns on the road. Regularly submitting these reports will create a culture of accountability and vigilance and overall safety and efficiency in the transportation operation.

Exterior Vehicle Inspection

Lighting and Indicators

Check your lighting and indicators regularly for safety. Look at brake lights, turn signals, and license plate lights. Make sure they are working and visible. This will prevent accidents and compliance with road safety regulations.

Brake System Components

A thorough check of the brake system is required. Check the brake pads, brake hose, brake chamber, and brake drum. Make sure the brake pads have the minimum required thickness to avoid brake failure. For air brakes check the air compressor, air lines, and air pressure gauges to make sure the system is working and there are no leaks or pressure issues.

Tires and Wheels

Check the lug nuts, and tire pressure and look for any visible leaks. Check for excessive heat which could be an underlying issue. Proper tire maintenance will prevent blowouts and vehicle stability.

Suspension and Steering

Check the steering wheel, tie rod, spring mounts, leaf springs, and shock absorber. These are critical to control the vehicle. Make sure they are free from wear and damage and securely attached to prevent steering issues and a smooth ride.

Body and Frame

The body and frame of your vehicle including the trailer frame, cross members, and skid plate should be inspected for any damage or wear. Make sure everything is properly mounted and connected. A well-maintained frame supports the structural integrity of the vehicle and safe and reliable operation.

Regular exterior vehicle inspections are the foundation of safety and performance. By going through each component you can identify potential issues before they become major problems.

Engine Compartment Inspection

Coolant Hose and Water Pump

Check the coolant hose and water pump for any visible leaks. Coolant levels must be maintained for engine cooling and to prevent overheating. Check the oil pressure gauge to make sure it’s within safe operating range.

Air and Power Systems

Check the air compressor and power steering components. Make sure there are no leaks in the air system that will affect braking. Check the power steering fluid level and inspect the hoses for any wear or leaks. These systems must be functioning properly for vehicle control and safety.

Electrical Systems

Battery Connections

Check the battery connections regularly to make sure they are clean, secure, and free from corrosion. Secure connections will prevent electrical issues and ensure the smooth start and operation of the vehicle.

Wiring and Lighting Indicators

Inspect the vehicle’s wiring for any wear or damage. Make sure all lighting indicators including headlights, brake lights, and turn signals are working. Properly functioning electrical systems are crucial for visibility and safety, especially during night or bad weather.

Regular inspection and maintenance of engine components, air and power systems, and electrical systems will ensure the overall reliability and safety of your vehicle. Addressing issues early will prevent major and costly repairs later on.

Trailer Inspection

Trailer Brake System

Check the trailer brake system thoroughly. Check the trailer brakes including the parking brake and brake pedal. Make sure all components are in good working condition to control and safety during stops.

Landing Gear and Related Components

Check the landing gear and its components including the release arm. Make sure all parts are greased to prevent wear and smooth operation. Make sure all connections are secure to prevent shifting during transport.

Trailer Frame and Connections

Inspect the trailer frame for any damage or wear. Make sure all mounting bolts are tightly fastened and the trailer is aligned with the towing vehicle. Alignment and secure connections will maintain stability and prevent handling issues on the road.

Trailer inspections are the key to safe operation and preventing breakdowns or accidents. By going through each component you can identify and address issues before they affect the trailer’s performance or safety.

Interior Vehicle Inspection

Cabin Safety and Comfort

Check cabin safety and comfort by:

- Seat Belt: Make sure it’s working and secure.

- Emergency Equipment: Check for the presence and condition of emergency tools like reflective triangles and a first aid kit.

- Fire Extinguisher: Make sure it’s properly mounted and fully charged for emergencies.

Dashboard and Controls

Check dashboard indicators and controls for optimal performance:

- Tire Air Pressure Gauge: Make sure the air pressure gauge is showing accurate readings within recommended levels. This is best done by manually checking the tires as the dashboard is not always accurate.

- Oil Pressure Gauge: Check the oil pressure gauge for any anomaly or fluctuation.

- Lighting Indicators: Check all lighting indicators including warning lights and signals are working.

Other Interior Checks

Check other interior components for operational readiness:

- Windshield Wipers: Check the condition of windshield wipers for wear and tear, and make sure they can provide clear visibility.

- Windshield Washer Fluid: Check the windshield washer fluid reservoir is full for effective windshield cleaning.

- Secured Items: Make sure all items inside the cabin are secured to prevent movement and potential hazards during transport.

Interior vehicle inspections will promote safety, comfort, and operational efficiency. Addressing issues early will maintain vehicle reliability and ensure a safe driving environment for all occupants.

Final Checks and Documentation

Finish the Inspection

Final checks:

- Final Walk-around: Do a final walk-around of the vehicle to make sure nothing was missed during the inspection.

- Check for Anything Missed: Double-check all checked components to make sure they meet safety and operational standards before moving on.

Documentation and Compliance

Document and comply:

- Filling Out Pre-Trip Inspection Reports: Fill out pre-trip inspection reports accurately, and document all findings, repairs, or concerns.

- Keep Records Up to Date: Make sure all inspection records are up to date and compliant with regulatory requirements. Organize records for easy reference and audit purposes.

CDL Pre-Trip Inspection Tips

Preparing for the CDL pre-trip inspection test requires thorough preparation and knowledge of the common areas of focus. Test takers should get familiar with inspecting critical components like brakes, tires, lights, and steering. Make sure to memorize the sequence of inspection and practice verbalizing each step. Tips to pass include practicing consistently, using mnemonic devices to remember the sequence, and staying calm and focused during the test. Familiarity with the process and attention to detail will get you through the CDL pre-trip inspection test.

Conclusion

Consistency is key in pre-trip inspections. By making these inspections a part of every trip, drivers are contributing to the ongoing safety and reliability of their vehicles. Consistent checks will identify potential issues early, prevent costly repairs, and make sure vehicles are always ready for the road ahead. This proactive approach will not only make drivers safer but also minimize downtime and improve overall fleet efficiency.

Make sure to promote safe practices among drivers by emphasizing the importance of pre-trip inspections. Remind them that these inspections are not just a requirement but a proactive measure to protect themselves, their cargo, and others on the road. Encourage them to take pride in their vehicles and safety above all. By promoting a culture of diligence and responsibility we can all make the roads safer and uphold professional driving standards.